Features & Models

VACUUM REGULATORS

Archer Instruments manufactures five different models of Vacuum Regulators, for use in vacuum-feed gas chlorination systems and gas sulfur dioxide systems. The primary function of a Vacuum Regulator is to serve as a normally closed, diaphragm operated inlet valve for the vacuum system. The inlet of the Vacuum Regulator is connected to the pressurized gas source, while the outlet is connected to the rest of the vacuum feed system. When vacuum is applied to the regulator, the internal diaphragm acts upon and unseats the spring-loaded inlet safety valve, allowing gas to enter the system under vacuum. If the operating vacuum is lost for any reason, the spring-loaded inlet safety valve shuts to prevent any pressurized gas from entering the system.

A secondary function of most Vacuum Regulators is to serve as a safety relief “vent” valve. Over periods of continuous operation, conditions such as dirty gas, residues accumulating on internal surfaces, lack of preventive maintenance, etc. can all contribute to a condition known as “venting” where small amounts of gas leak past the inlet safety valve during times while there is no operating vacuum. This pressurized gas should be relieved at very low pressure to a safe location (the outside atmosphere). Every Vacuum Regulator manufactured by Archer Instruments incorporates an internal safety relief “vent” valve and is equipped with a second outlet connection for venting gas to be routed to the outside atmosphere.

Other secondary functions of Vacuum Regulators can include:

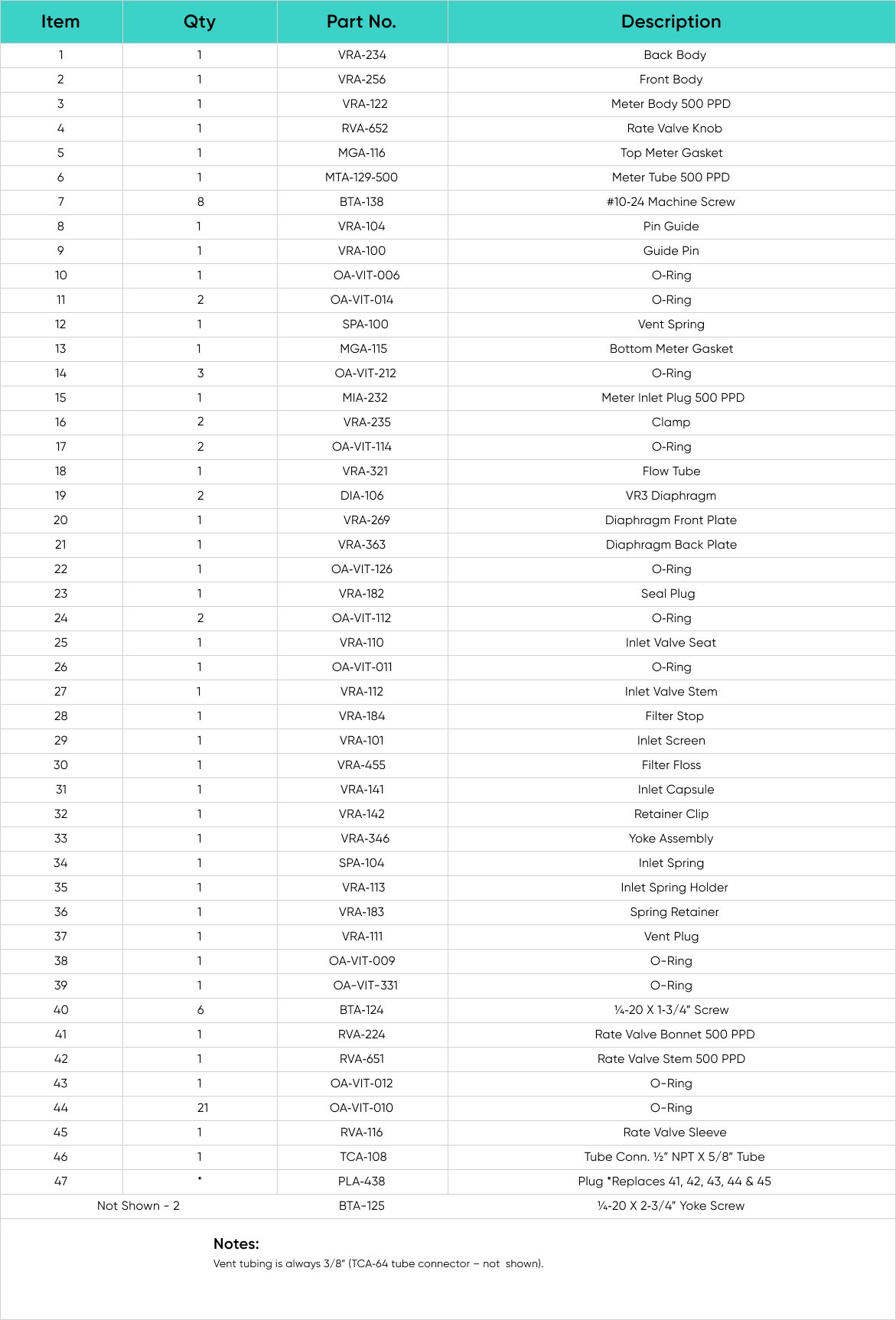

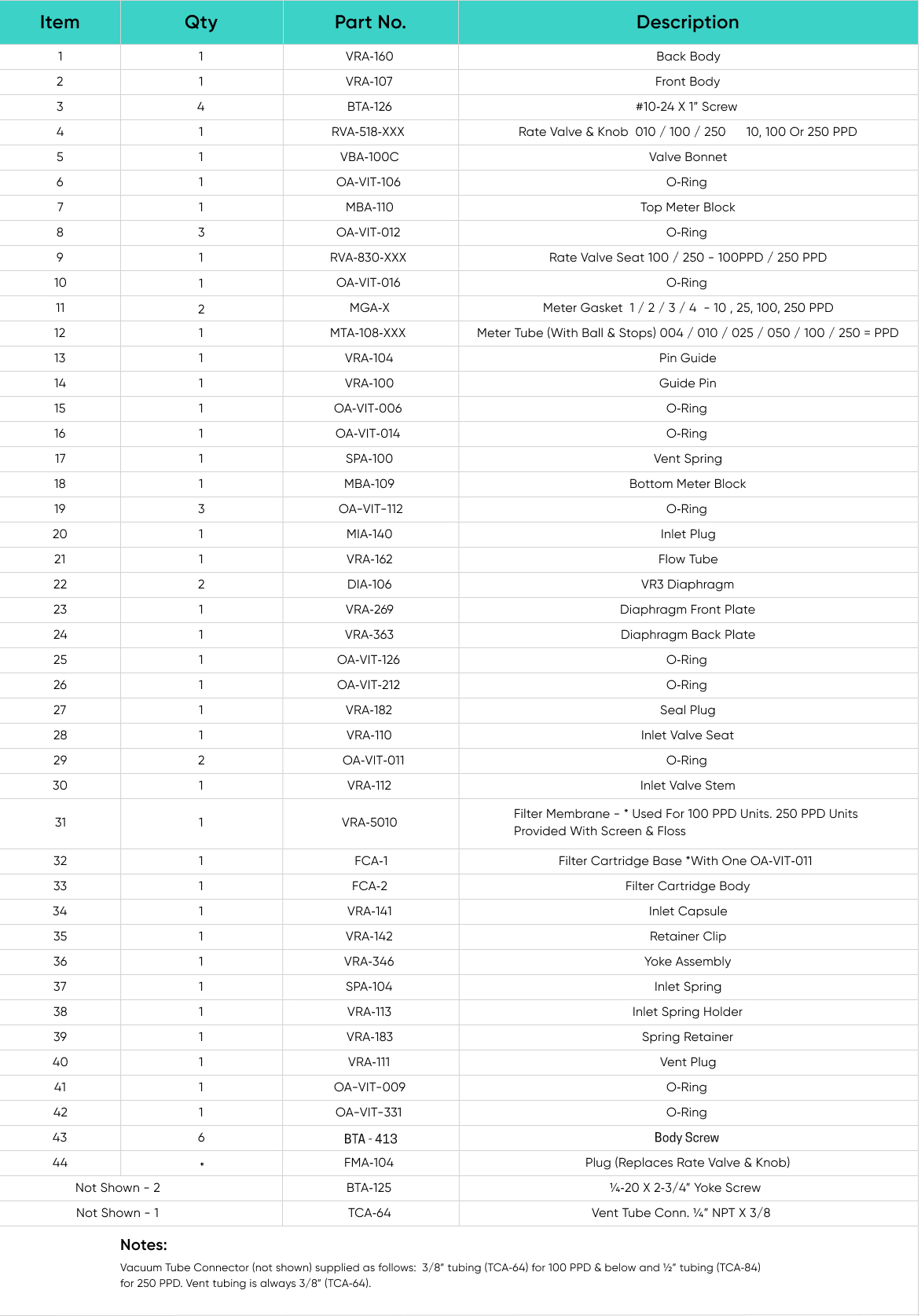

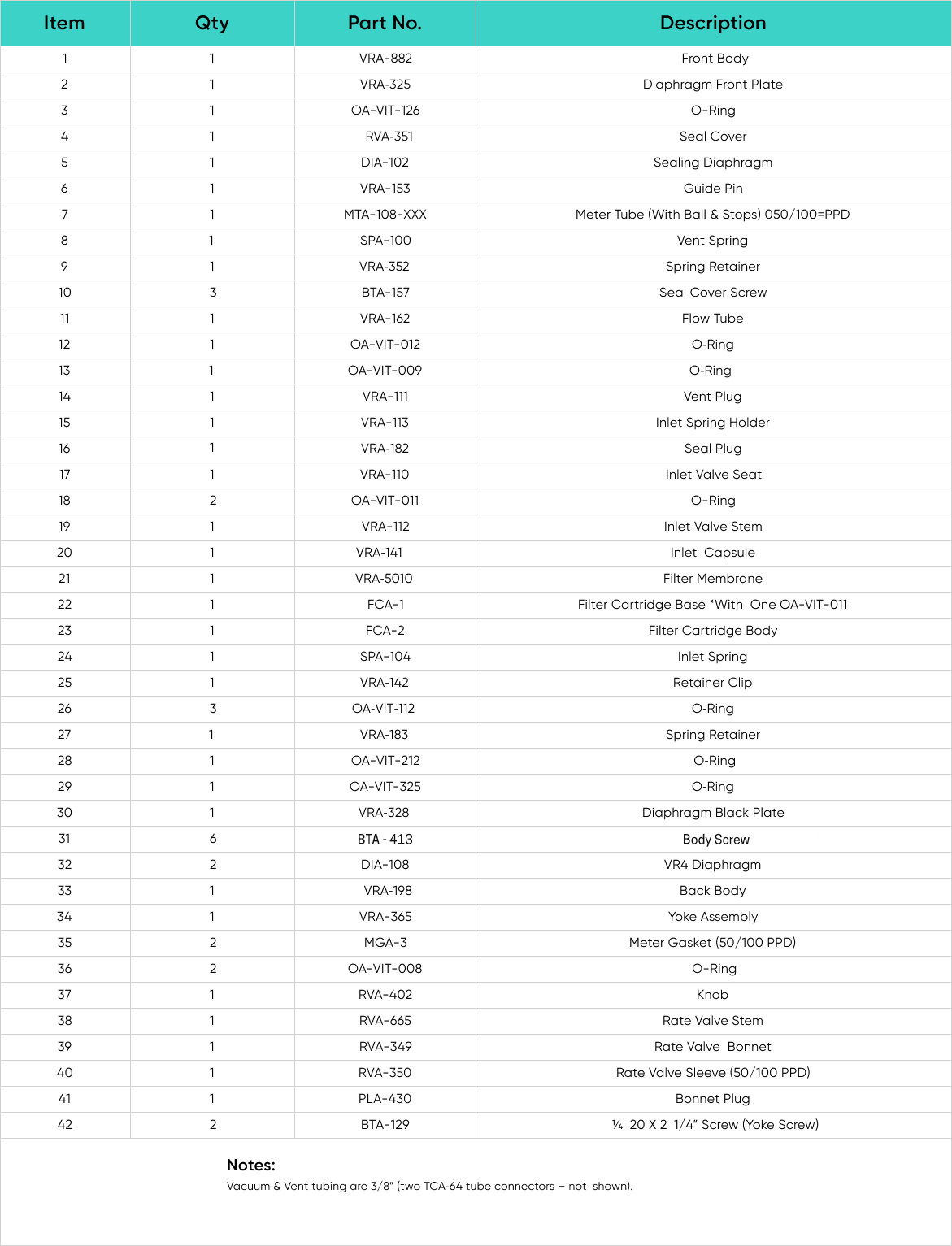

- The incorporation of a graduated glass meter tube for local visual indication of the gas feed rate. This is a standard feature on the Archer Instruments Models VR3 and Model VR4 Vacuum Regulators and is an optional item for the Archer Instruments Model VR6 and Model SR9 Vacuum Regulators.

- The incorporation of a manual rate control valve for local gas feed rate adjustment. This is an optional feature on the Archer Instruments Models VR3, Model VR4, and Model VR6 Vacuum Regulators.

- The incorporation of built-in automatic switchover capability. This is a standard feature on the Archer Instruments Model SR9 Vacuum Regulator. These regulators are designed for use in pairs (or more than two units) and each regulator is equipped with a mechanical detent mechanism that holds the unit in a standby position until the original gas supply has been emptied. This design allows for uninterrupted operation when the initial gas source goes empty.

Every Archer Instruments Vacuum Regulator is manufactured using all machined parts. No parts are injection molded. Only the best materials are used for each part.

Archer Instruments Vacuum Regulator information:

– Sizes from 4 PPD (75 g/hr) up to 500 PPD (10 kg/hr)

– Integral glass meter tube & optional rate valve

– Sizes from 4 PPD (75 g/hr) up to 100 PPD (2 kg/hr)

– Integral glass meter tube & optional rate valve

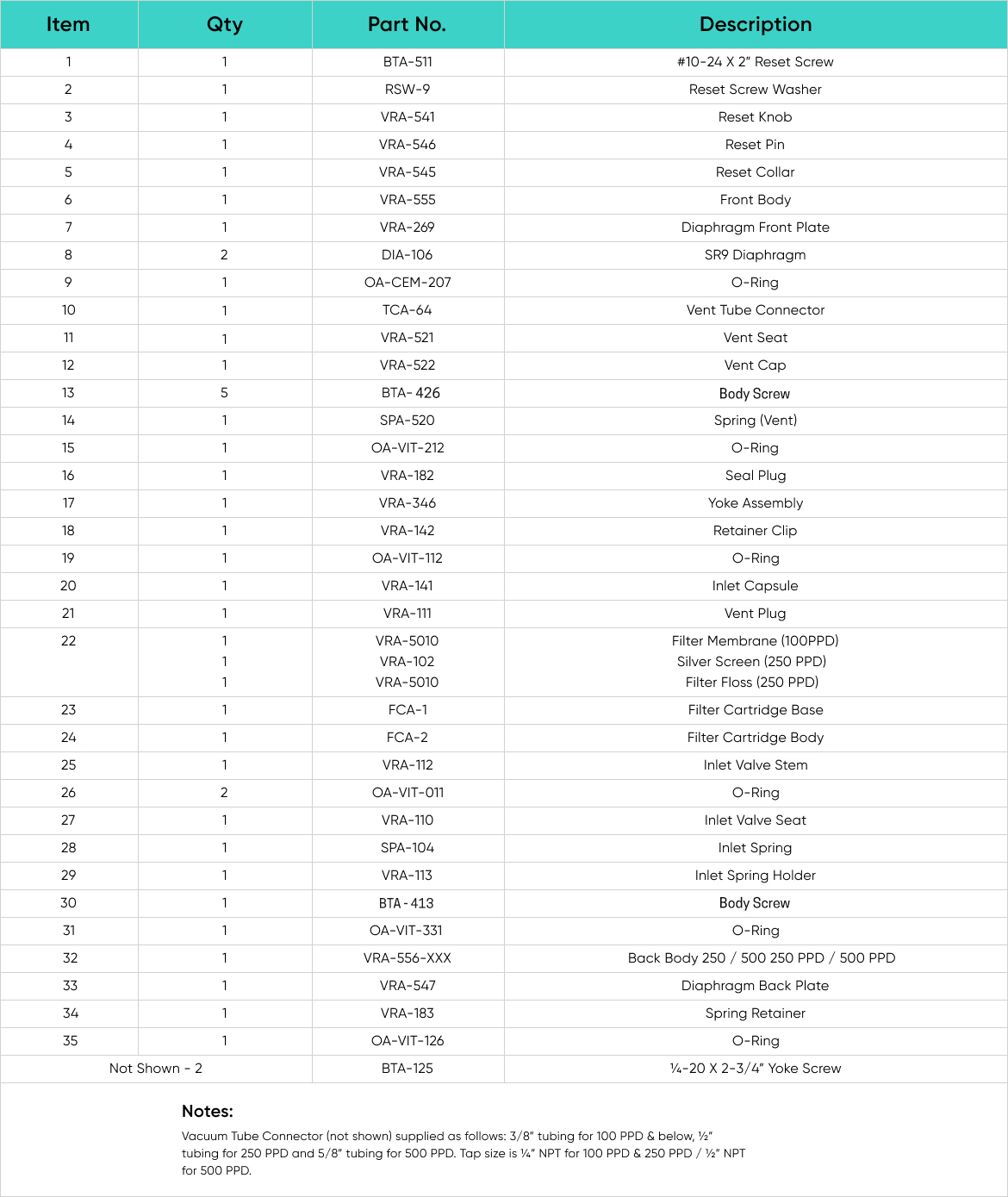

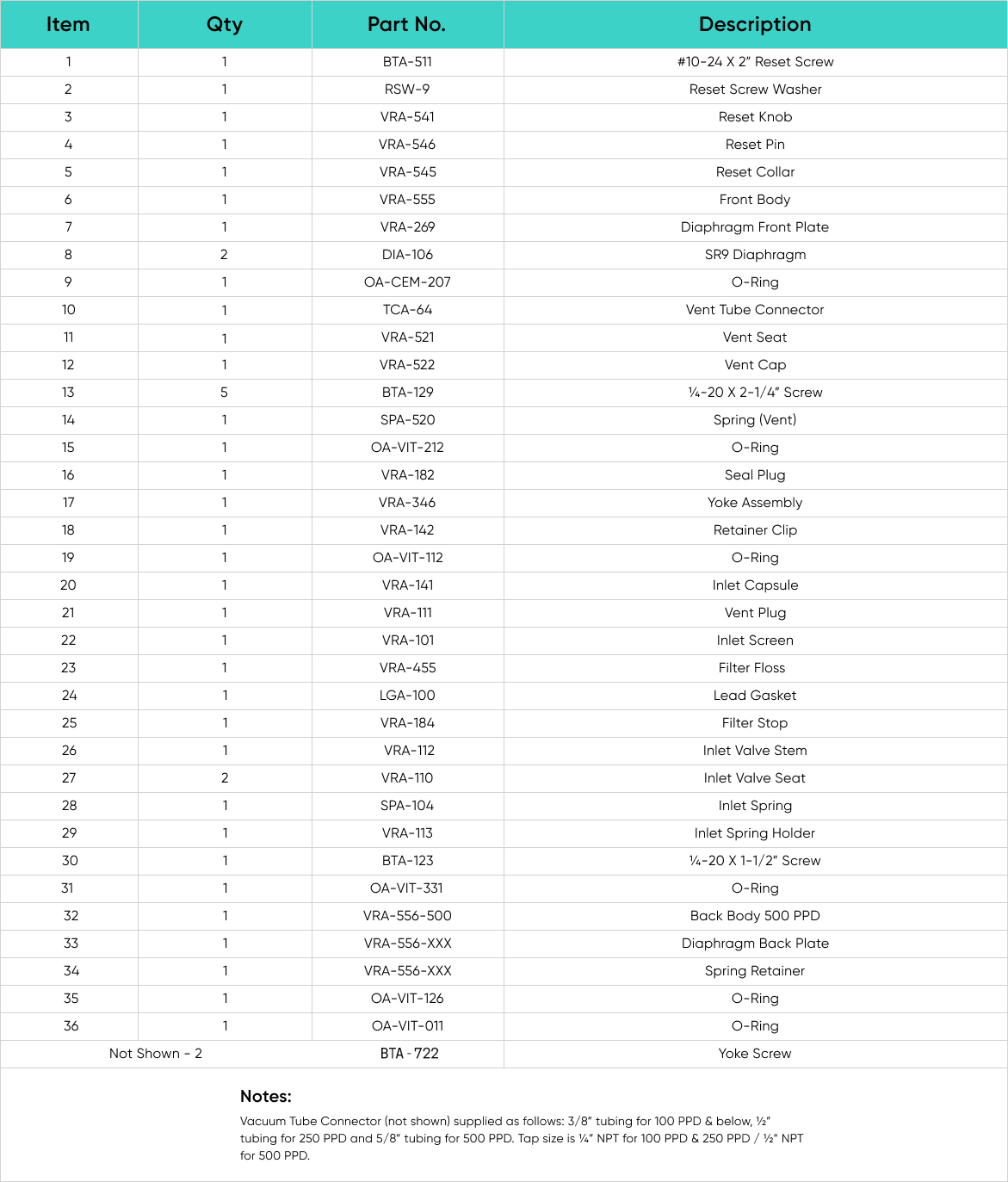

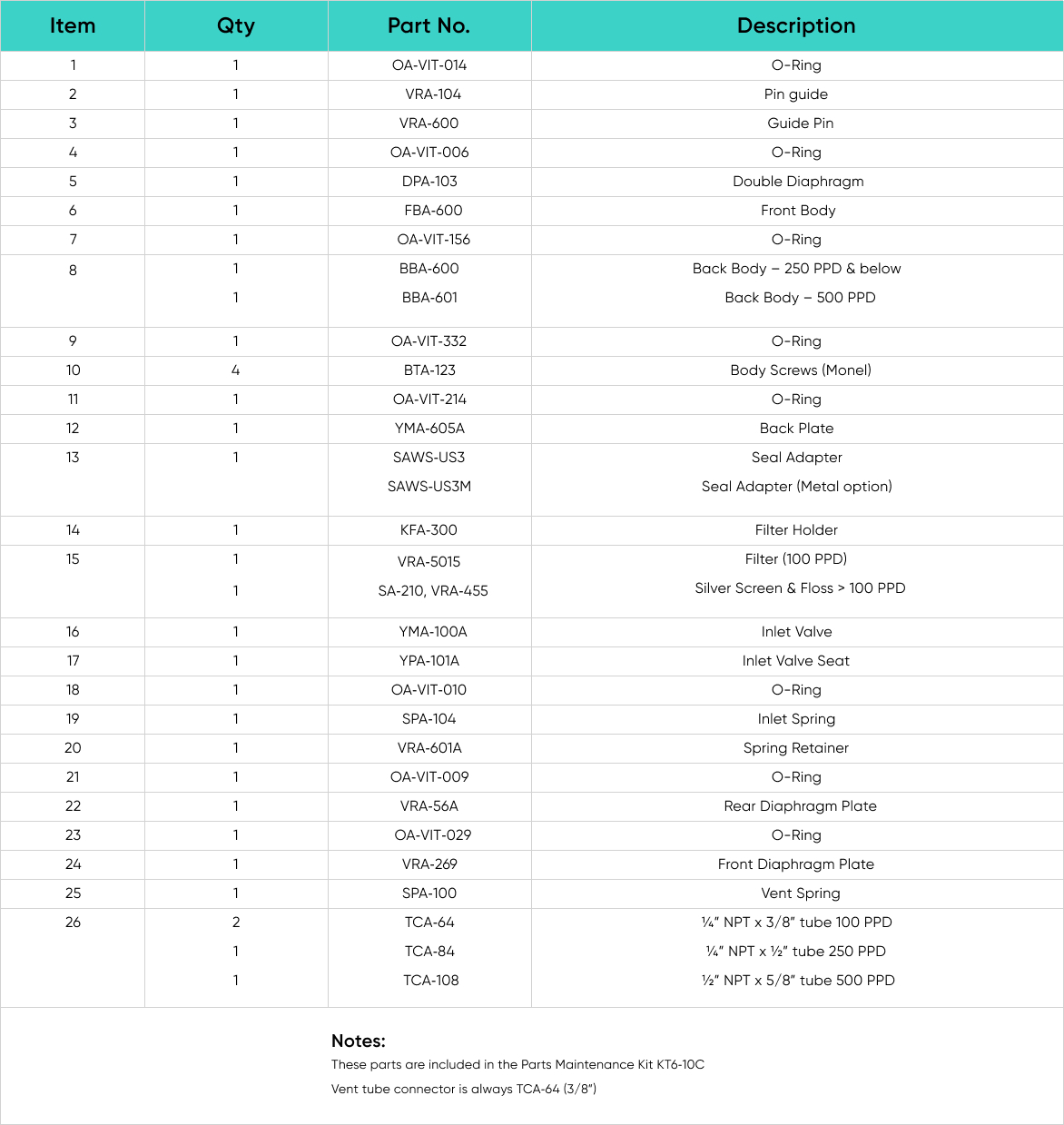

– Sized for either 100 PPD (2 kg/hr), 250 PPD (5 kg/hr) or 500 PPD (10 kg/hr)

– Optional attached glass meter tube and / or rate valve

– Sized for either 100 PPD (2 kg/hr), 250 PPD (5 kg/hr) or 500 PPD (10 kg/hr)

– Optional attached glass meter tube

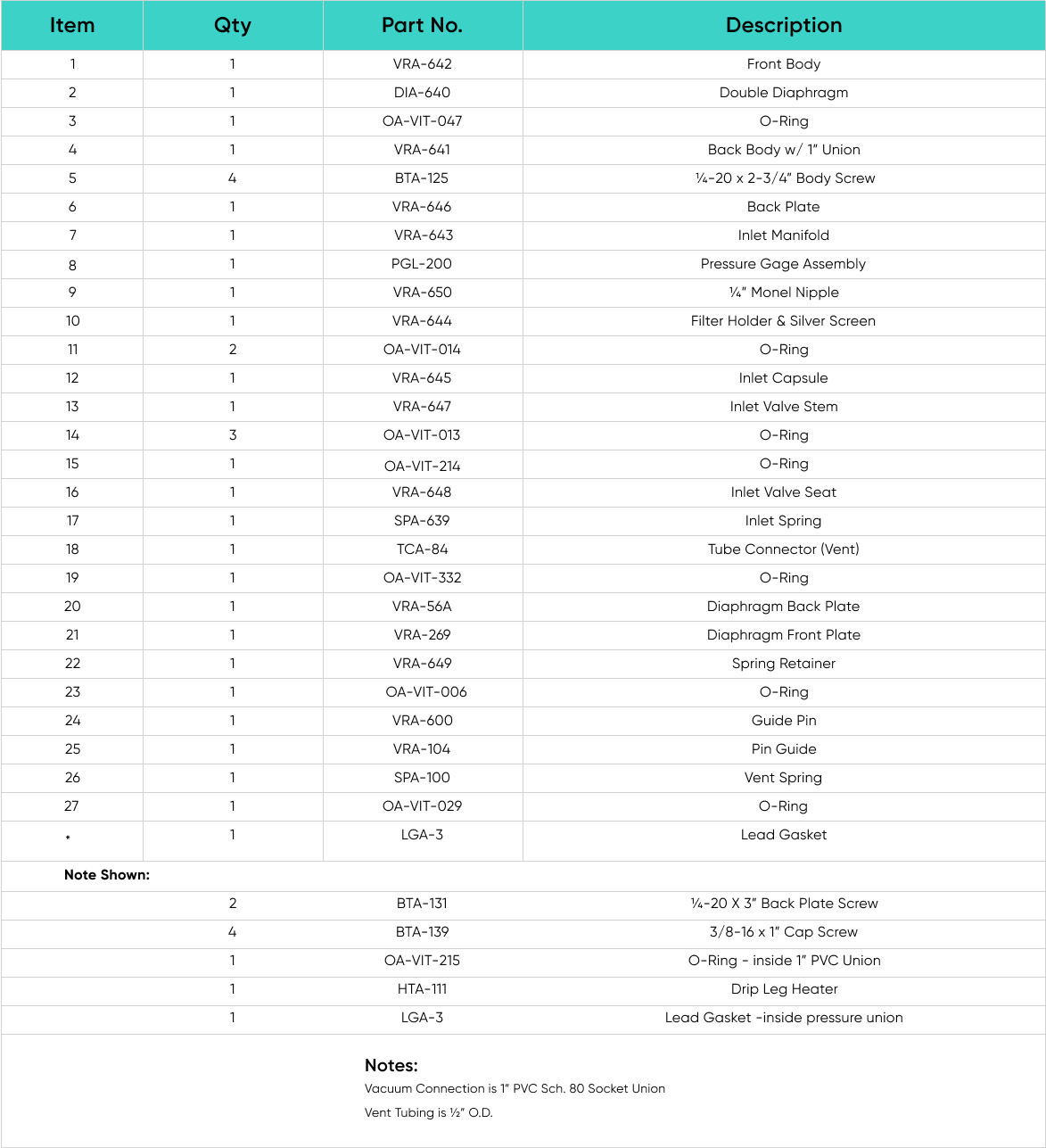

– Capable of up to 2,000 PPD (40 kg/hr)