Features & Models

ACCESSORIES

Check Valve Model

Accessories A-345 Adapter

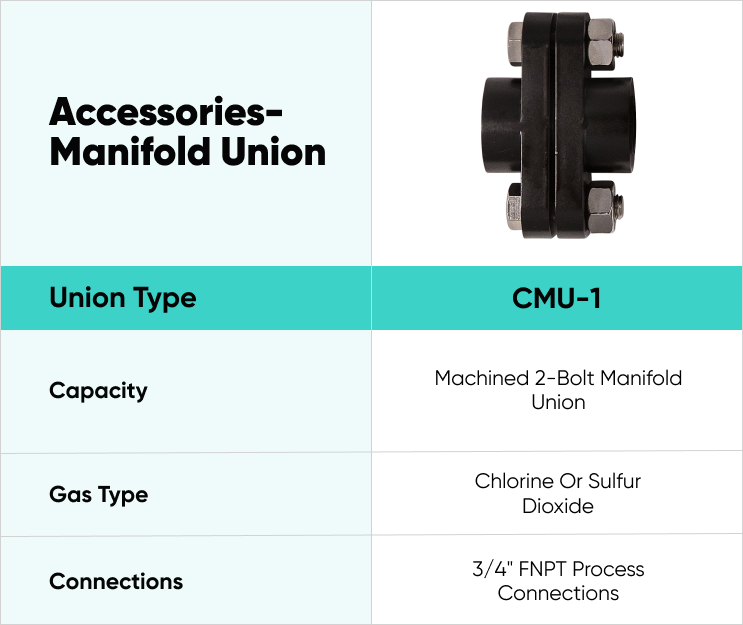

Accessories Manifold Union

Accessories VGA-450 Vent Guard

Accessories Modular Vent Valves

Accessories Main Connects

Isolation Valve Assembly

Archer Instruments manufactures a line of accessory products designed for use in gas chlorination systems, gas sulfur dioxide systems, and various other chemical feed applications.

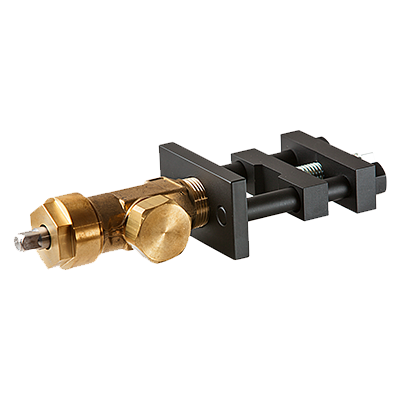

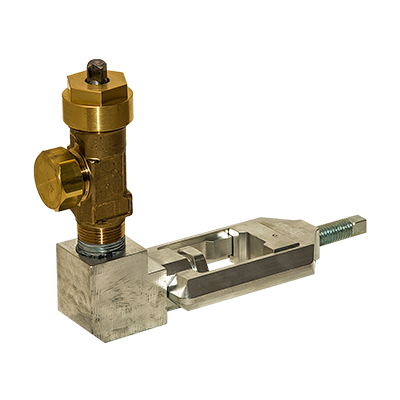

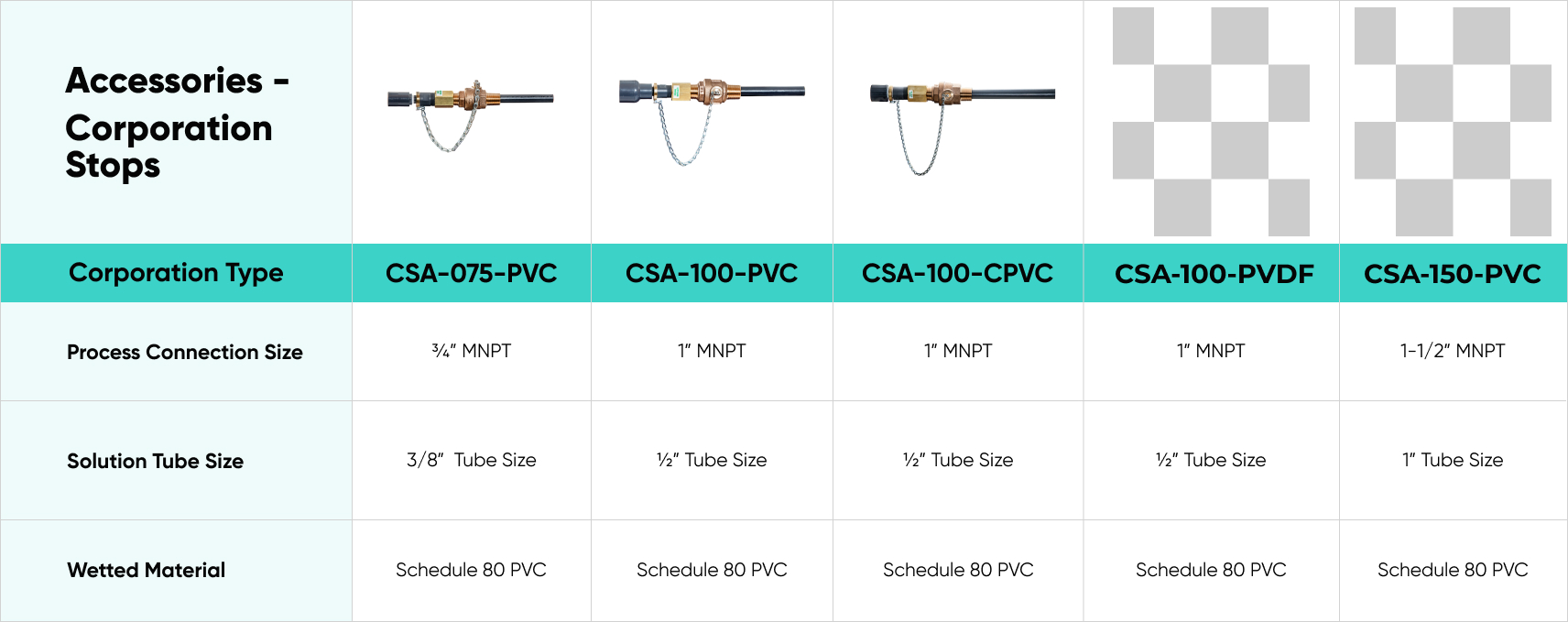

Corporation Stops

When injecting chemical solutions into process pipes it is always advisable to introduce the chemical into the process flow away from the inner wall of the process pipe, in order to minimize chemical attack or chemical deposits on the wall of the pipe and to improve rapid dilution/mixing. Corporation Stops provide a chemical injection connection into pressurized process pipes, which can be retracted and removed while the process pipe remains pressurized. Archer Instruments corporation stops are an “open flow” design with no internal check valve. These are ideal for use in gas chlorination systems, where a check valve would create backpressure to interfere with the proper operation of the Ejector venturi nozzle.

The size of the Corporation Stop assembly refers to the pipe size of the male NPT threads used to install the assembly into the process connection (pipe tap or saddle).

| Size | Model # | Wetted Material |

|---|---|---|

| ¾” | CSA-075-PVC | Schedule 80 PVC |

| 1” | CSA-100-PVC | Schedule 80 PVC |

| 1” | CSA-100-CPVC | Schedule 80 CPVC |

| 1” | CSA-100-PVDF | PVDF (Kynar) |

| 1-1/2” | CSA-150-PVC | Schedule 80 PVC |

Main Connects (also known as “quills”)

Main Connects are another option that allows for chemical introduction away from the inner wall of the process pipe. These are machined from a single piece of material and offer male NPT threaded connections for both the inlet and the process connection. Archer Instruments offers ½”, ¾” & 1” sizes in machined PVC material.

Check Valves

Archer Instruments manufactures several types of check valves, designed specifically for use in vacuum-based gas chlorination systems or for use in sulfur dioxide gas systems. These check valves are all spring-loaded with Hastelloy-C springs.

Archer Instruments SCV-1 check valve is a ball check valve for gas feed systems smaller than 100 PPD or 2 kg/hr.

Archer Instruments DCV check valves offer the highest level of reliability in preventing water from flooding critical system components, such as meter panels and vacuum regulators. We’ve incorporated a long-proven design from existing ejector check valves and employed only the highest quality materials of construction. The DCV check valves are offered for gas feed capacities up to 500 PPD or 10 kg/hr.

Archer Instruments CVA-2000 is a high-capacity diaphragm style check valve for gas feed capacities up to 2,000 PPD or 40 kg/hr.

Isolation Valves

Archer Instruments manufactures two designs of isolation valves – the IVA-1 and IVA-830. Both designs incorporate a captured steel yoke design to comply with the standards of the Chlorine Institute as well as a Sherwood chlorine valve. The IVA-830 yoke allows for easy use of popular valve closure actuators and the design is also ideal for applications where the shape of the cylinder does not allow for directly mounting the vacuum regulator.

Modular Vent Valves

While all Archer Instruments vacuum regulators are designed and manufactured with integral safety relief “vent” valves, there are vacuum regulators manufactured by other companies which do not incorporate this function. In systems using vacuum regulators that do not have built-in relief valves, it is necessary to install a separate device to act as a relief valve for venting gas. Archer Instruments manufactures a line of Modular Vent Valves for gas feed capacities up to 500 PPD or 10 kg/hr.