Features & Models

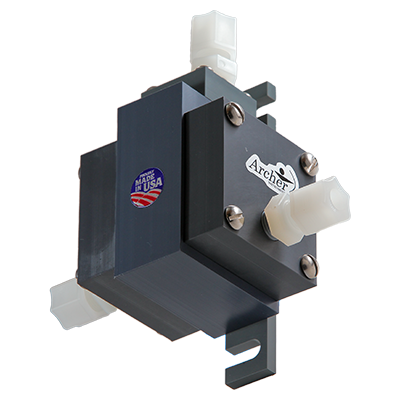

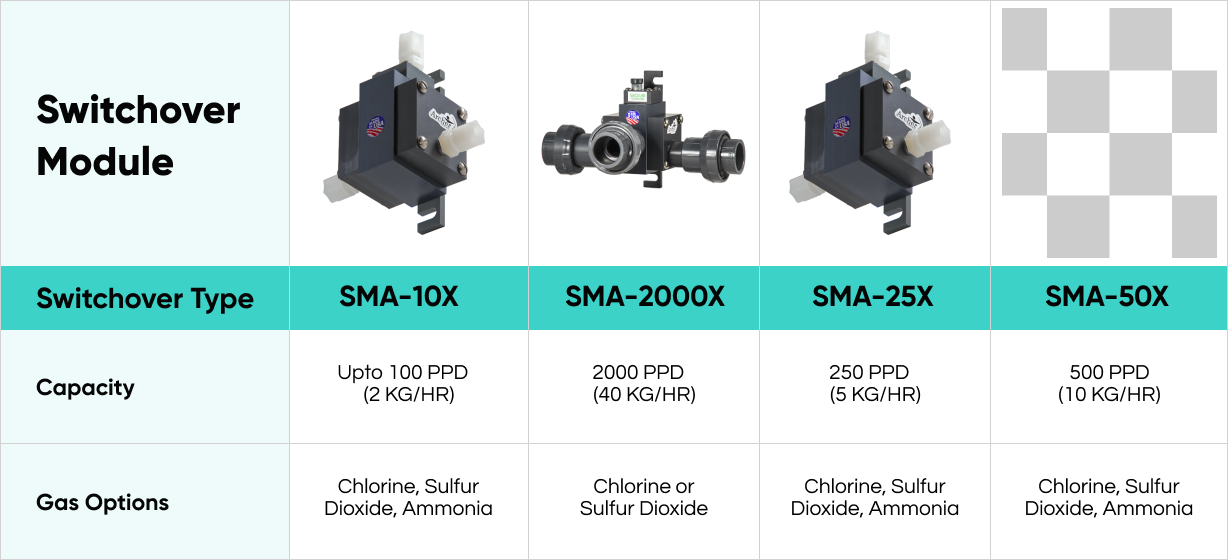

SWITCHOVER MODULE

Archer Instruments manufactures Automatic Switchover Modules designed for use in gas chlorination systems, sulfur dioxide systems, and ammonia gas systems. For each different gas application, the Automatic Switchover Modules are produced with internal parts made of materials specifically selected for the gas of intended use and must be ordered specifically for the gas of intended use.

Automatic Switchover Modules are designed to allow for two gas sources to be employed so that one gas source is in use while the second (isolated) gas source is left in a “standby” condition. The Automatic Switchover Module is installed in the system between the Remote Meter Panel and the two gas sources, with the outlet connected to the Remote Meter Panel and the two inlets connected to each of the two gas sources (vacuum regulators). The internal design of the

Automatic Switchover Module ensures that one gas source is always isolated, while the other gas source is in use. A spring-loaded pivot assembly inside the Automatic Switchover Module keeps the standby gas source isolated during normal operation. When the gas source in use becomes empty, the operating vacuum level inside the system will increase. This increasing vacuum level then applies force (via the internal diaphragm) against the internal spring-loaded pivot assembly, overcoming the spring tension and switching the position of the Automatic Switchover Module to open the gas feed from the standby gas source. The depleted gas source is simultaneously isolated. This allows for uninterrupted operation of the gas feed system, regardless of when the first gas source becomes empty. Operation personnel can then replace the depleted gas cylinder or container, which then automatically becomes the new “standby” gas source.

Archer Instruments Automatic Switchover Modules are offered in four sizes as follows.

SMA-10C–Offered for capacities of 100 PPD (2 kg/hr) or less

Manufactured with 1/4” female NPT process connections and provided with tube connectors for 3/8” tube

SMA-25C–Offered for capacities of 250 PPD (5 kg/hr) or less

Manufactured with 1/4” female NPT process connections and provided with tube connectors for 1/2” tube

SMA-50C–Offered for capacities of 500 PPD (10kg/hr) or less

Manufactured with 1/2” female NPT process connections and provided with tube connectors for 5/8”tube

SMA-2000C–Offered for capacities of 2,000 PPD (40 kg/hr) or less

Manufactured with 1” female socket PVC Sch80 union connectors

Every Archer Instruments Automatic Switchover Module is manufactured using all machined parts. No parts are injection molded. Only the best materials are used for each part.

Note: It is important to understand that gas feed systems are comprised of two vacuum sections. The division of these two sections is the rate control valve, which creates a significant restriction to the gas flow. The section between the vacuum source (ejector) and the restriction (the rate control valve) is known as the high vacuum section, where vacuum levels typically range from 12 Hg to 25 Hg depending on the relationship bet ween the ejector nozzle and gas feed rate. The section between the restriction (the rate control valve) and the gas source(s) (the vacuum regulators) is known as the low vacuum section, where vacuum levels reflect the operating vacuum level of the vacuum regulators, typically between 1Hg and 4Hg depending on the model of vacuum regulator being used and the gas feed rate. For the proper function of the Automatic Switchover Module, it is important to understand the module must be installed in the low vacuum section of the gas feed system. This is because the Automatic Switchover Module operates on the principle of rising vacuum level, which occurs when the in-use gas source is depleted. For this reason, it is very important that the only rate control valve used in the system be located at either the remote meter panel or an automatic control valve, which must be installed between the Automatic Switchover Module and the ejector. Vacuum regulators which incorporate rate control valves must be “plugged” (rate valve removed) when using an Automatic Switchover Module.