Features & Models

AMMONIA GAS FEED

Ammonia Equipment Ejectors

Ammonia Equipment Remote Meters

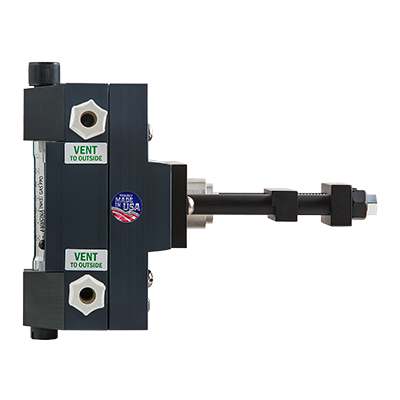

Ammonia Vacuum Switchovers

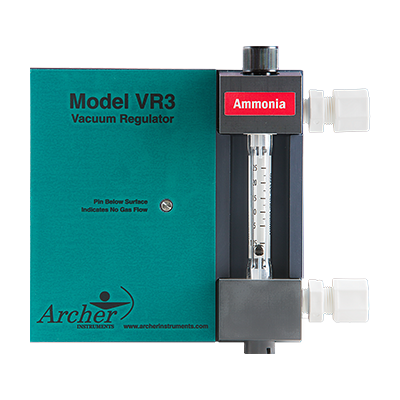

Ammonia Vacuum Regulators

Archer Instruments manufactures a complete line of products for vacuum-based Ammonia gas feed. This includes the following components manufactured specifically for use with Ammonia gas:

EOA-25A (100 PPD NH3) – 1-1/4” male NPT process connections

EOA-50A (250 PPD NH3) – 1-1/4” male NPT process connections

MPA-25A (100 PPD NH3)

MPA6-50A (250 PPD NH3)

SMA-25A (100 PPD NH3)

SMA-50A (250 PPD NH3)

VR3-25A (100 PPD NH3) – includes integral glass meter tube & optional rate valve

VR3-50A (250 PPD NH3) – includes integral glass meter tube & optional rate valve

SR9-10A (50 PPD NH3) – includes integral switchover mechanism

SR9-25A (100 PPD NH3) – includes integral switchover mechanism

SR9-50A (250 PPD NH3) – includes integral switchover mechanism

Automatic Control Valves: Our Model ACV10 Automatic Control Valve is offered for Ammonia gas in ranges of 12, 25, 50, 100, or 250 PPD NH3 gas

Gas Leak Detectors: Our GLD30 Gas Leak Detector is offered with Ammonia gas sensors

Ammonia gas is significantly different in multiple ways from Chlorine gas or Sulfur Dioxide gas. The most important differences to understand are

- Ammonia gas will interact differently with certain materials, as compared to Chlorine gas or Sulfur Dioxide gas. The materials selected for internal parts must be specifically chosen based upon their chemical resistance for the gas of intended use. For this reason, it is critically important that gas feed products only be used with the gas of intended use. It is similarly important that future maintenance procedures be done with the chemical-specific spare parts, as identified in the product literature.

- The relationship between temperature and the evaporation of Ammonia gas inside of cylinders is very different, as compared to Chlorine or Sulfur Dioxide gases. When considering the type or quantity of Ammonia gas cylinders to employ in a system design, it is important to note that the ability of a cylinder to absorb heat from the atmosphere and to thereby evaporate the Ammonia gas inside is roughly 40% of what would be experienced with a Chlorine gas cylinder.

- Ammonia gas has a dramatically different molecular weight, as compared to Chlorine gas or Sulfur Dioxide gas. The easiest way to understand this difference is to consider the weight of the gas in comparison to the weight of normal air. Chlorine and Sulfur Dioxide gases are heavier than air. However, Ammonia gas is considerably lighter than air. This is important to understand for two reasons. First, heavier or lighter gases flowing through the same graduated glass meter tubes will indicate very different feed rates. For this reason, the graduated glass meter tubes are made specifically for the gas of intended use. Secondly, the location of gas leak detector sensors must be selected according to the gas to be monitored. Chlorine and Sulfur Dioxide gas sensors should be located relatively low on the wall (knee level is a good rule-of-thumb). Conversely, Ammonia gas sensors should be located fairly high on the wall, near the ceiling.